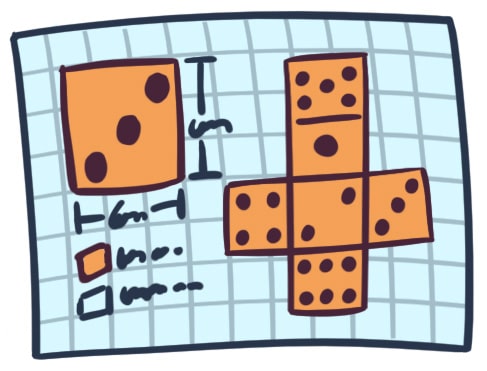

Dice design guidelines

Dice are one of the most ubiquitous items in the board game industry. You can use them for almost anything, design them in every shape, colour and size you like. Because a dice is not just limited to numbers, you can put (almost) any image on there. And on top of that, it’s just fun to roll dice. When you’re designing dice for your game, it is important to keep a few things in mind.

First of all, check what type of dice (material) you will be using. There are some minor yet not insignificant differences between the different types of dice. The different types will be explained in detail below, as well as in this article. The vast majority of dice are made from resin, acrylic or wood. The differences between resin and acrylic dice mostly stem from different production methods, as they are similar in appearance for the most part. The choice between resin and acrylic dice depends on the quantity needed. Besides the choice for dice material, there are different methods to put the design on the dice.

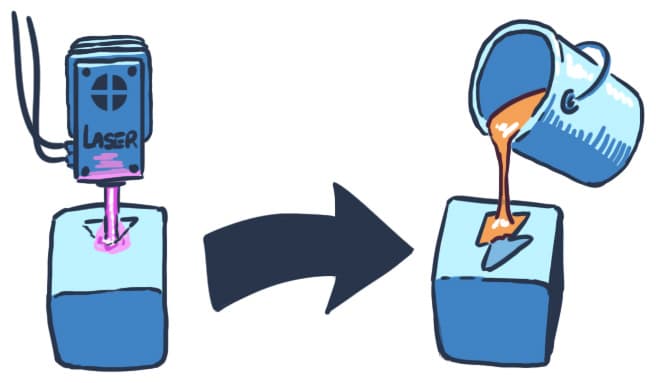

Laser engraved

A laser engraved dice has layers of the surface burned off with a laser. The laser is extremely precise and this allows your design to be lasered into the surface. The design can vary from anything like icons, logos or numbers. Laser engraving can be used on acrylic, resin and wooden dice.

The advantage of laser engraving is that they have a much lower initial set up cost. As they don’t require molds, the design is directly programmed into the laser machine. This does mean a slightly higher costs per dice when excluding the molding fees. Downside is that it is slightly less precise and clean than molded dice.

After the shape is lasered into the dice, paint can be applied to the carved spaces. Especially with contrasting colors, this makes the image on the dice easy to read and helps it stand out. Keep in mind that it is more difficult for lighter paint colors to completely cover dice with a very dark base color. This is particularly true if there are many small areas in the design. Another color, or a design that allows for a larger connected area, could be a better choice then.

Molded

A molded dice is made by creating a mold according to the design. Once the mold is complete, resin or acrylic is injected into the mold to create the final dice. Doing this allows for the highest level of detail in the design of the die face. After the shape of the die is set, the depressed (lower) areas of the die can be coloured in with paint.

Both acrylic and resin dies are made using molds. However, the molds are different for the materials. Resin molds wear out faster, and as such are more suitable for lower quantities. Acrylic molds are more resilient and can be used for a longer time before they wear out and break, but they are more expensive to make.

File preparation

Although in theory any design can be put on a die, reality is a bit different. To make sure your idea comes out flawless, there are some things to keep in mind. Due to the nature of the material and the size of a die, very thin lines don’t work very well. Nor do a lot of different elements grouped together too closely. Thus, it is best to design it so that there is enough space between the different elements. As a rule of thumb, lines should be at least 0.6mm thick. Furthermore, the whole design needs a 2mm margin around the edges. This is to make sure the entire design is on the dice, even if it shifts slightly during production.

The submerged parts of the die can be painted too. For this, the colors need to be specified in pantone colors for each icon. And you can only use spot colors for dice. You can use one color per die face but the die faces on 1 single die can be different. For a normal die with 6 die faces, you can select up to 6 different colors!

The files containing the design of the dice should be in a vector format. This can be Adobe Illustrator, PDF or EPS. Please separate different dice designs into different files. And make sure to label them correctly.

Silk Screen

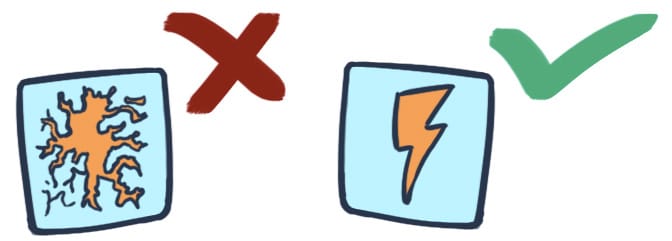

Besides molded & engraved dice, there is also another way to get a design onto a die face. Silk screen printing can be applied to the die face. This means that all sides of the die will be flat, with no carving or relief. The benefits of silkscreen are that they are not limited to 1 color per die face. And they don’t require molding costs for setup. If you have a very detailed design with multiple colors, silk screen can be a good choice.

Since silk screen dice are not limited to 1 color, the design process allows for more freedom. However, a die is still a small item. As such, too many details have the chance of being lost when printing. Furthermore, the resolution of silk screen printing is lower than normal printing. So very intricate details are more difficult to print correctly. For silk screen, CMYK colors can be used. The file should be one of the standard image file formats, such as Photoshop.

Complex shapes

Maybe you have a really cool idea for your dice. One where the edges are shaped like tentacles, or maybe each die face has a creatures face, where the amount of eyes the creature has equal the amount of pips!

At Boda Games we are happy to discuss you how to achieve this striking custom dice, giving you a choice of materials and processes.

Sorry, the comment form is closed at this time.