Artwork guides – white lines when exporting to PDF

White lines that appear in exported PDF’s are a common question we get from customers. In the process of preparing all the artwork for their board game, artwork files are commonly exported as PDF’s. These PDF’s are sent to Boda Games and we check whether they are ok for manufacturing. Quite often we get concerned messages from customers who cannot understand why their exported PDF is showing white lines. And more importantly, whether these white lines will show up when we start printing the paper components. We will explain why the white lines appear when exporting to a PDF and how to prevent that from happening. In this guide, we are using InDesign from Adobe.

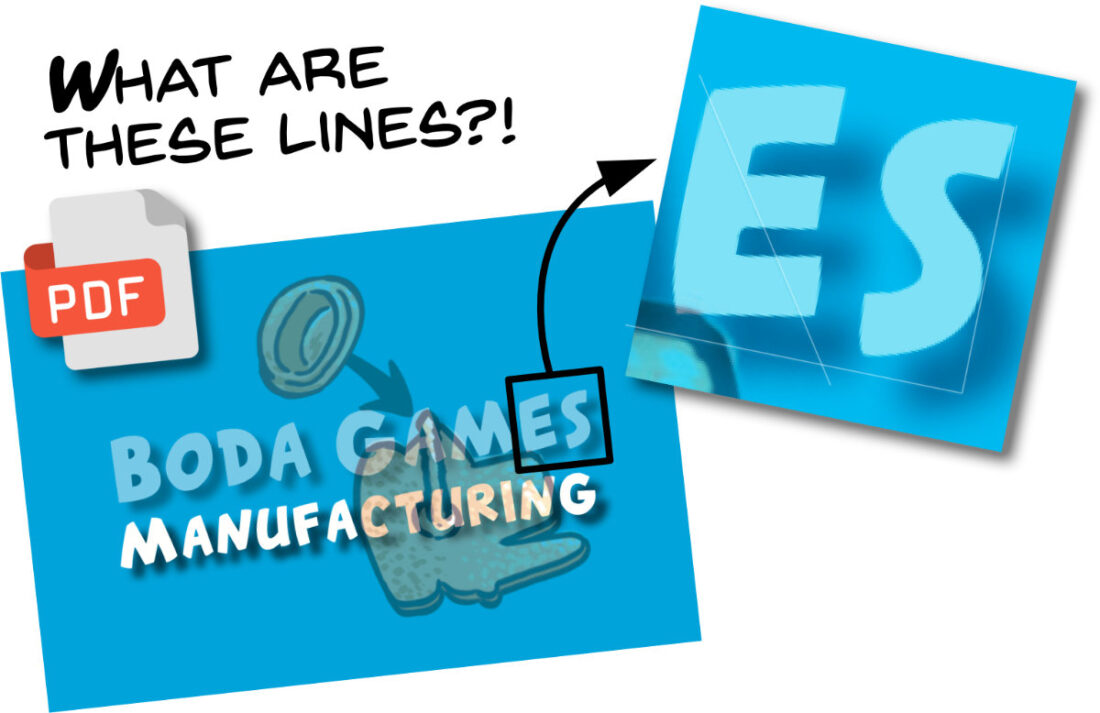

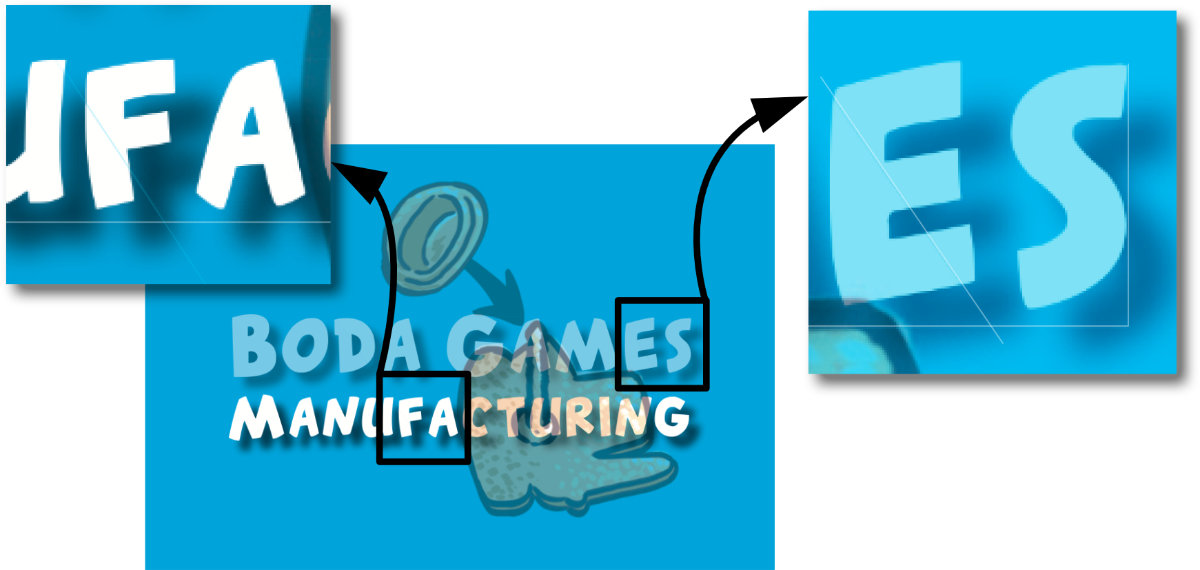

Another example of artifacts appearing in a PDF file

Why white lines are visible

First of all, in general the white lines that are visible will not show when printing on a high resolution device, even if they are visible on low resolution devices such as monitors. The reason these appear is due to image flattening in combination with anti-aliasing and the existence of transparency effects in the file. When you flatten on export, the page gets cut up into pieces. The way the page gets cut up is handled by the Transparency Flattener preset that is chosen under the Export Advanced tab. If the file is saved in a format that does not support transparency, such as Acrobat 4 / PDF version 1.3, the white lines may occur.

Flattening transparency means “faking it” by creating opaque areas that look transparent. But these opaque areas have to fit together like a mosaic, each piece right next to the next. The result is that sometimes white peeks out between them. In the vast majority of cases, this appears only on screen. Sometimes it shows up on low-resolution printers, too, but virtually never in high-res commercial output.

How to avoid this

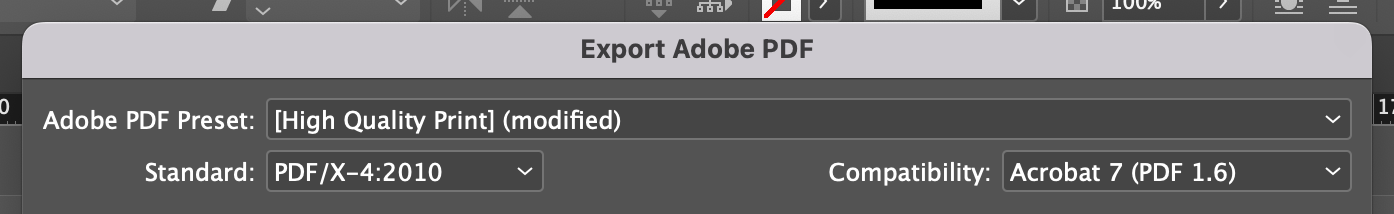

To prevent this from happening, we need to adust the settings when exporting the file to PDF. Set the standard to PDF/X-4:2010 and check that the compatibility is set to Acrobat 7 (PDF 1.6). With these settings, the problem shouldn’t occur and the files look exactly like they should.

Remember to export the PDF using a modern standard to avoid artifacts appearing in documents

Still have further questions? Send us an email and we’ll gladly help you with any problems you may have.