Printing on wooden components

Wooden components are a staple of board games for as long as they have been around. They fit together perfectly with paper cards and punchboard game boards to create the classic board game experience. Everyone knows the piles of wooden cubes, discs and rectangles that are so common euro style games. However, you can do a lot of things with wooden components, both in terms of size and shape as well as printing. The three most commonly used methods for printing artwork, numbers and symbols on wooden components are silk screen printing, heat transfer printing and UV printing. Even though they overlap in certain areas, each of these printing methods has their own advantages. Picking the right one for the components in your board game will elevate the experience. We will explain the process, the advantages and the limitations for each of them.

Silk Screen Printing

Silk screen printing is done by pushing the ink through a stencil or screen. The screen is made of a fine mesh material that is stretched across a frame. In the screen, the areas where the ink should flow through are left open, and the other areas are blocked. Then, ink will be applied to the screen on one side, and the other side of the screen will be placed against the wooden component. A squeegee is used to push the ink across the screen, letting it flow through the areas that are open. That ink adheres to the wood and forms the design. Then, the parts will be laid out to let the ink dry, so it sets and adheres to the wood.

Benefits:

Silk screen printing produces a very durable print. The mesh screens allow for highly detailed, intricate design. The colours are vibrant and mask the underlying color well.

Downsides:

For each color a separate screen is necessary. For small print runs, it requires an investment in the screens. The set up and production process can be time-consuming. Gradient colours and photographic graphics cannot be done by silk screen.

UV printing

UV printing is done with a large UV printing machine that prints the UV ink onto the wooden component. In the UV ink there are special compounds that harden when exposed to UV light. Much like your printer at home, this is done line by line as it builds up the graphic from top to bottom. After printing, it immediately cures it with UV light. This rapidly solidifies the ink on the surface of the wood. This process makes the ink resistant to smudging and more durable.

Benefits:

UV printing allows for high resolution, full colour printing with a fine level of detail. The colours are vibrant and opaque. UV printing can easily accommodate variable data, such as numbers or unique designs on each component.

Downsides:

UV printing prints on the surface, so it has a higher potential for rubbing off due to abrasion. It does not mask the underlying paint color as well as silk screen printing.

Heat Transfer Printing

Heat transfer printing is done by first printing the design on a special carrier paper with special heat transfer inks. The paper is placed over the wooden component(s) and aligned. Then, the heat press machine simultaneously heats the paper and applies pressure to it. The heat activates the ink and causes it to subliminate from the carrier paper and adhere onto the wood. Finally, the carrier paper is removed. The wooden components then cool down to allow the ink to set.

Benefits:

Heat transfer printing allows for full colour printing with high detail and resolution. The process is suitable for small and large production volumes. Heat transfer can be applied to a variety of surfaces, including textures ones. Setup time and cost is low.

Downsides:

It is less durable when regularly exposed to moisture or abrasion. The texture of the wood affects the print quality. It is less suitable for dark surfaces, as the heat transfer print does not cover the underlying color as well as silk screen printing.

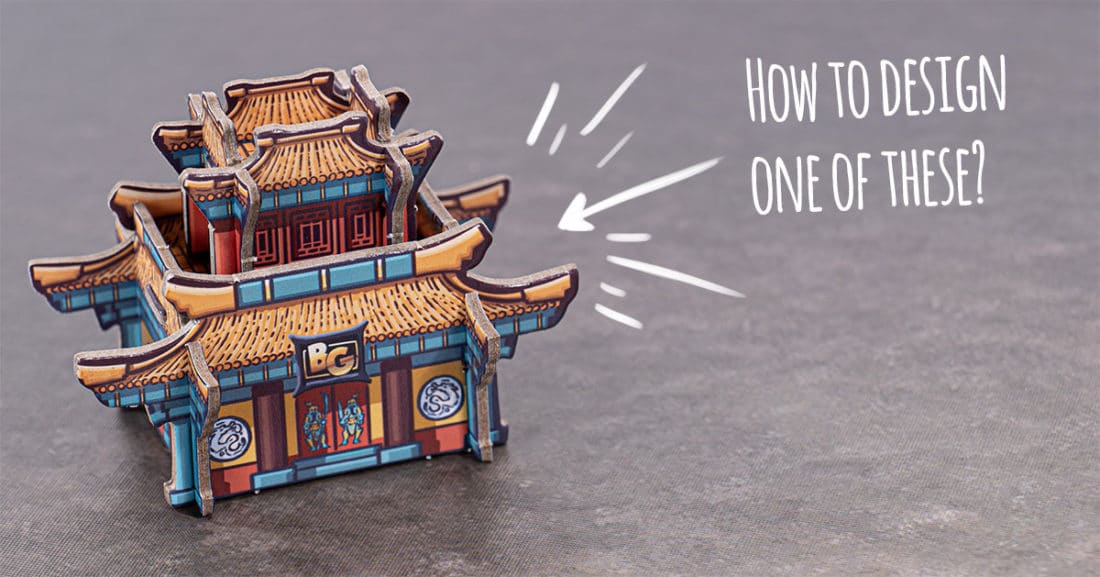

Want to see more examples of wooden components Boda Games Manufacturing has produced? Have a look at the wooden components section on our website, as well as our brochure. Have an idea for printing wooden components for your next board game? Get in touch with us!